There are four general body styles of ball valves: single body, split body, top entry, and welded. There are four general types of ball valves: full port, standard port, reduced port, and v port.

A full port ball valve has an oversized ball so that the hole in the ball is the same size as the pipeline resulting in lower friction loss. Flow is unrestricted, but the valve is larger.

A standard port ball valve is usually less expensive, but has a smaller ball and a correspondingly smaller port. Flow through this valve is one pipe size smaller than the valve's pipe size resulting in slightly restricted flow. In reduced port ball valves, flow through the valve is one pipe sizes smaller than the valve's pipe size resulting in restricted flow.

A v port ball valve has either a 'v' shaped ball or a 'v' shaped seat. This allows the orifice to be opened and closed in a more controlled manner with a closer to linear flow characteristic. When the valve is in the closed position and opening is commenced the small end of the 'v' is opened first allowing stable flow control during this stage. This type of design requires a generally more robust construction due to higher velocities of the fluids, which would quickly damage a standard valve.

A trunnion ball valve has a mechanical means of anchoring the ball at the top and the bottom, this design is usually applied on larger and higher pressure valves(say 4 inch and above 600 psi and above) Manually operated ball valves can be closed quickly and thus there is a danger of water hammer. Some ball valves are equipped with an actuator that may be pneumatically or motor (electric) operated. These valves can be used either for on/off or flow control. A pneumatic flow control valve is also equipped with a positioner which transforms the control signal into actuator position and valve opening accordingly.

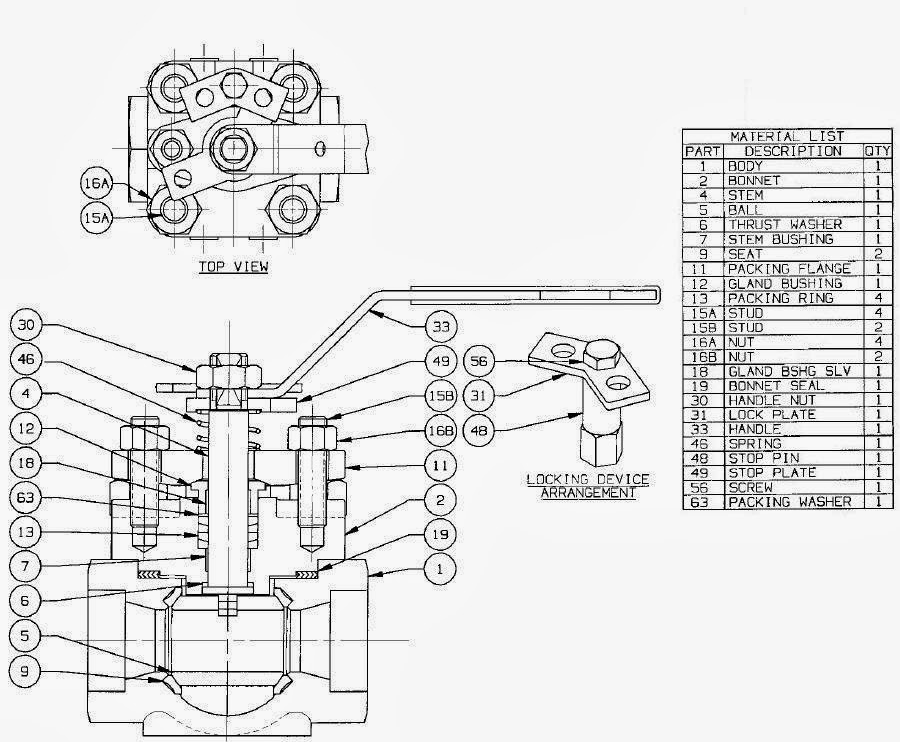

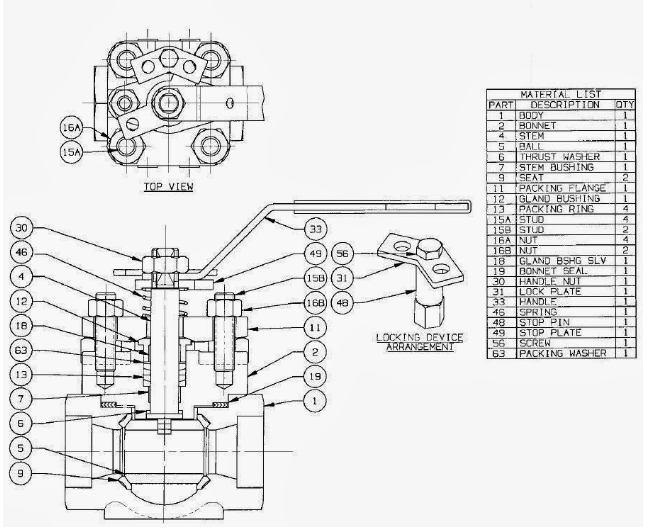

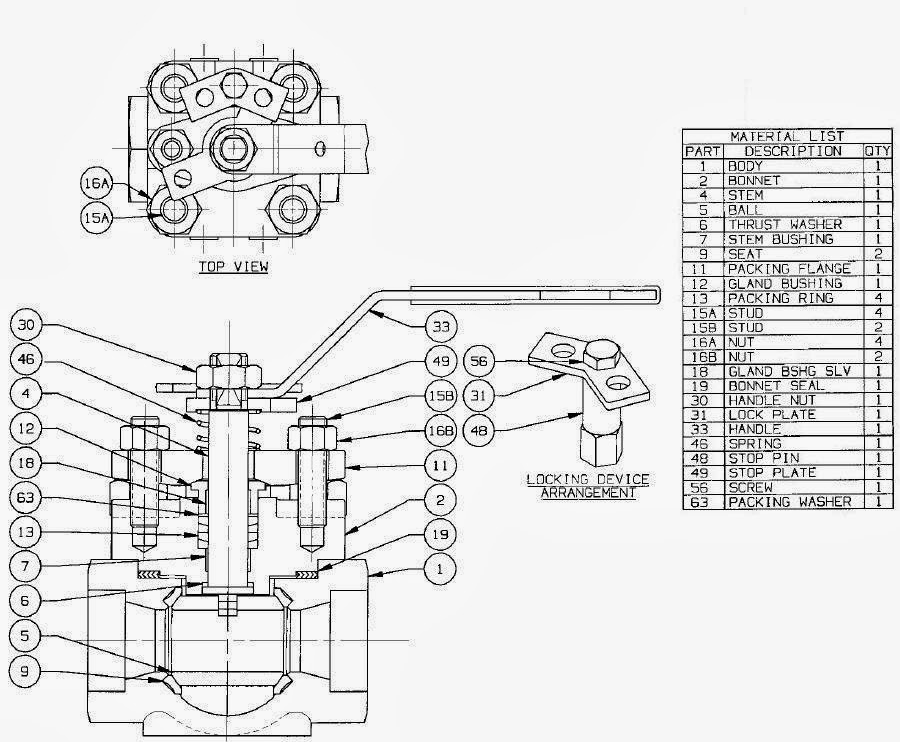

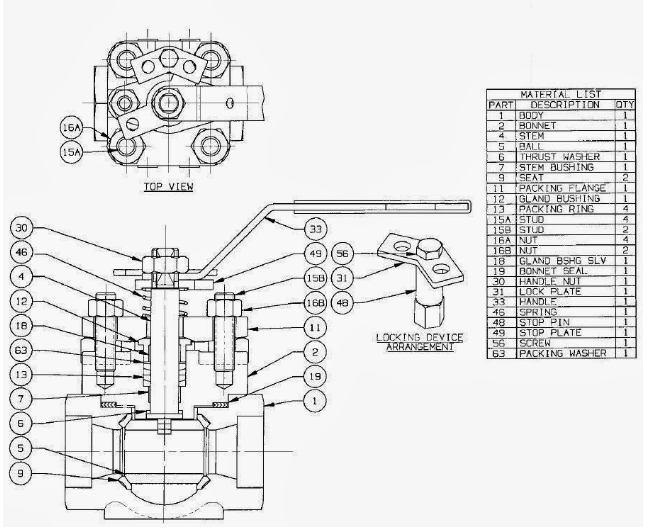

Construction of a ball valve

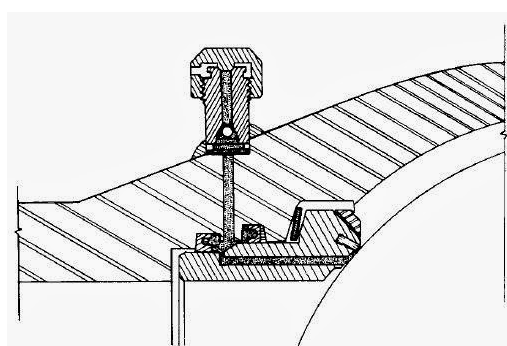

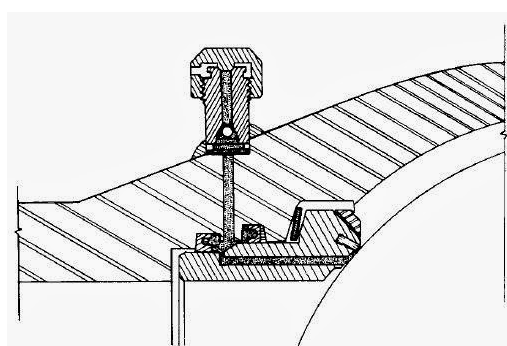

Major components of the ball valve are the body, spherical plug, and seats. Ball valves are made in three general patterns: venturi port, full port, and reduced port. The full-port valve has an inside diameter equal to the inside diameter of the pipe. In the venturi and reduced-port styles, the port is generally one pipe size smaller than the line size. Stem sealing is accomplished by bolted packing glands and O-ring seals. Valves are also available with a lubricant-seal system that is similar to that available for plug valves. A typical lubrication system is illustrated in

A ball valve may be unidirectional, bidirectional, or multi-directional, depending on the number of valve ports and the number of valve seats. Therefore, ball valves are referred to as 2-way, 3-way, 4-way, or 5-way multi-port valves. A 2-way ball valve with a single seat will be unidirectional with the flow direction indicated. Even a 3-way, 4-way, or 5-way ball valve can be unidirectional when flow must enter through a designated port. A 2-way ball valve provided with two seats, one on the upstream side and the other on the downstream side of the ball, is termed a bidirectional valve. Multiple-port ball valves permit flows in more than one direction, thus eliminating the need for several valves.

ball valve are manufactured in several different body configurations: top entry, side entry, split body, and three-piece body. The valve ends are available as butt welding, socket welding, flanged, threaded, soldering, or brazing ends.

ball valve are manufactured in high- and low-pressure classifications. The advances in ball valve designs have made it possible to use these valves in high pressure and high-temperature applications.

Types of Ball Valves

The following provides a brief description of types of ball valves:

Split-Body ball valve

The split body design consists of a two-part body, a cover, ball, seat rings, stem, and other internals. The two-part body is held together by a flange connection. One body part is smaller than the other. The ball is inserted in the larger body part, and the smaller body part is assembled by a bolted connection. The stuffing box is constructed integral with the larger body part. On smaller size split-body ball valves, the two-part body is joined by threaded connection. The flanged or threaded joint between the two-part body is an added source of potential leakage.

Flanged end connections are commonly available on all sizes; however, they are standard for large size valves. NPS 2 (DN 50) and smaller split-body ball valve are furnished with screwed ends. The split-body ball valves are manufactured in sizes ranging from NPS ¹⁄₂ (DN 15) through NPS 36 (DN 900).

Top-entry ball valve allow access to valve internals for assembly, dis-assembly, repair, or maintenance by removal of the valve bonnet-cover. The valve is not required to be removed from the pipeline.

End-Entry ball valve

End-entry ball valves have a single-piece body. The ball is inserted from one end and is retained by an insert. These valves have flange- or screwed-end connections. This design is commonly used for inexpensive small valves. They are also available in larger sizes up to NPS 6 (DN 150).

Three-Piece — Body ball valve

The middle part of the valve is the major part that holds all valve internals, and the stem passes through a hole in the top. Two end caps are held together with the middle body by bolts or studs and nuts. The end connections are part of the end caps, and they may be butt-welding, socket welding, threaded, or flanged. This design is available in sizes ranging from NPS ¹⁄₂ (DN 15) through NPS 36 (DN 900). The two end cap joints are two additional sources of potential leakage.

Double Trunnion Ball Valves

In this ball-valve design, the ball is provided with two integral short-shaft extensions called the top and the bottom trunnions. These trunnions are fitted in bearings and rotate freely when the shaft installed in the top trunnion is turned to open or close the valve. The ball is held firmly in place, unlike the ball in other designs where the ball is supported by the two seat rings and is allowed to float in the direction of the slot on top of the ball. A shaft installed in the top slot is turned to open or close the valve.

The trunnion-mounted ball-valve design is used with split-body large size valves, whereas the floating-ball design is the most common design for all other types of ball valves. The torque required to actuate a trunnion-mounted ball valve is substantially smaller than the torque required for a floating-ball design.

Lubricated or Non-lubricated ball valve

Like other valves, the stem sealing is usually accomplished by bolted packing glands and O-ring seals. Some valve designs are available with a lubricant-seal system similar to the one used in plug valves. Such a design is shown in Fig. 2. The valves with lubrication seal systems are termed lubricated ball valves, while others are called non-lubricated.