The fire fighting system is crucial for every business. Because a sudden fire event can be highly damaging to buildings, expensive equipment, documents, and inventory. Water sprinklers, smoke detectors, and fire suppression mechanisms are all part of a fire fighting system, and they all heavily rely on top-quality, highly-efficient valves to safely provide the right amount of water at the right time. Valves are the critical components of every system which involves the transport and supply of fluids. As water supply is essential in a fire fighting system, the piping must have suitable valves for accurate control of flow.

In this guide, we have discussed some important types of valves in fire fighting systems, which are:

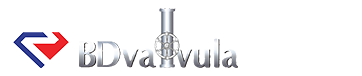

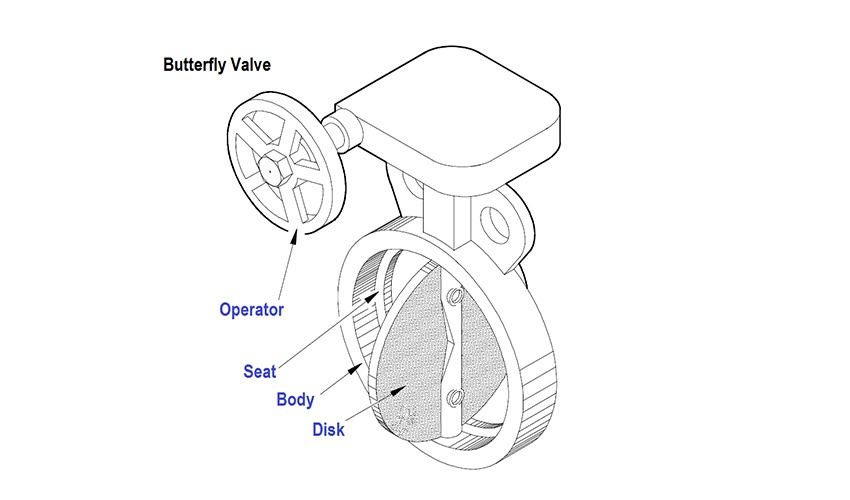

Butterfly Valve

Butterfly valve is also part of the quarter turn valve family. What makes butterfly valve distinct from the other valves is the flat to a concave disc that attaches to the valve stem.

Positioned in the middle of the valve with the stem bored into it or attached at one side, the disc blocks media flow when the valve is closed. The stem adds support to the disc. This design allows butterfly valve to throttle when there is incremental opening of the valve.

Advantages

● Compact design.

● Lightweight.

● Minimal pressure drop.

● Easy to install.

Disadvantages

● Limited throttling capabilities.

● Strong pressure may affect disc movement.

Applications

Butterfly valves are often used in water and gas applications where there is a need to isolate or interrupt the flow of media. Butterfly valves are great for processes that use large diameter pipes. They are also suitable for slurries, cryogenics, and vacuum services.

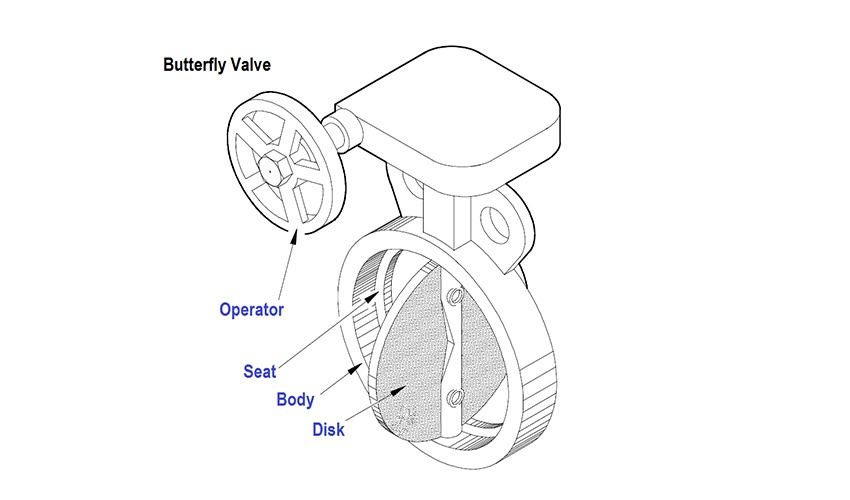

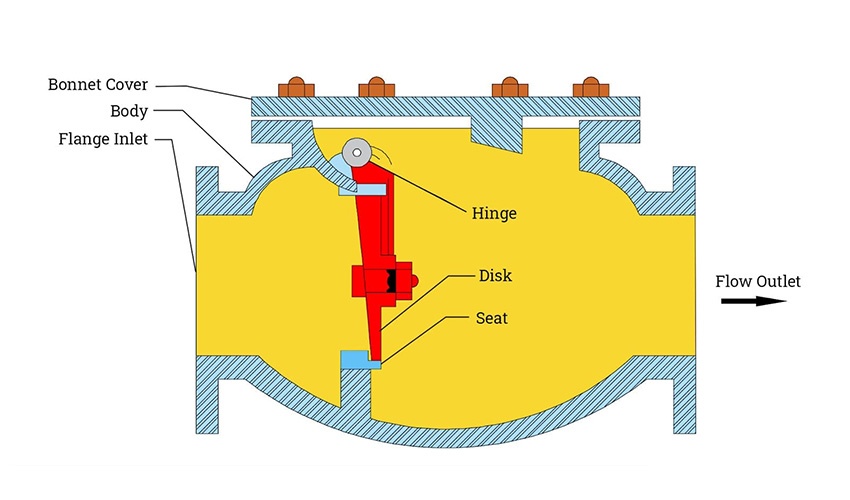

Check Valve

Check valve relies on internal pressure, instead of outside action, for opening and closing. Also known as non-return valve, prevention of backflow is the main function of a check valve.

Advantages

● Simple design.

● No need for human intervention.

● Effectively prevent backflow.

● Can be used as a backup system.

Disadvantages

● Not great for throttling.

● The disc may potentially get stuck in the open position.

Applications

Check valves are used in applications that need backflow prevention such as pumps and compressors. Feed pumps in steam boilers often use check valves. Chemical and power plants have a variety of processes that also utilize check valves. Check valves are also used when there is a combination of gases in one pipeline.

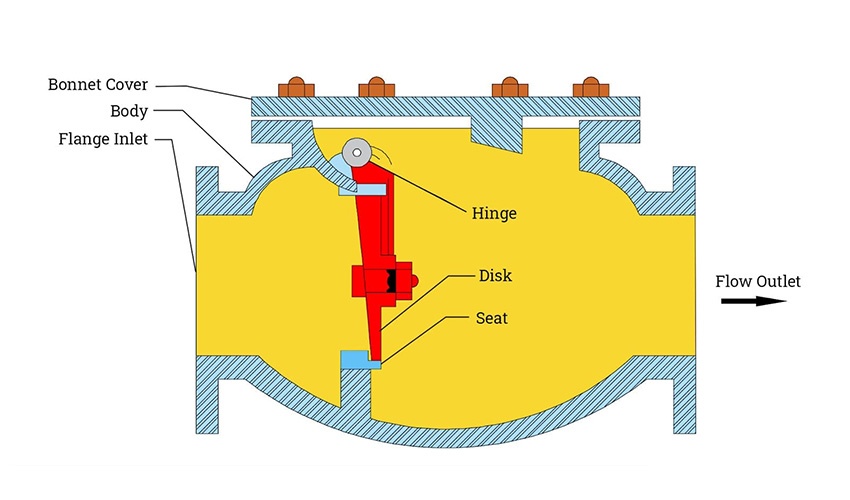

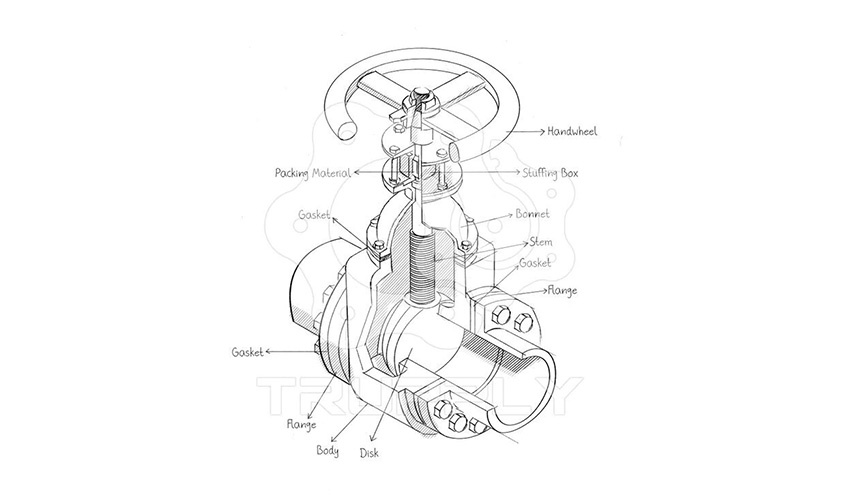

Gate valve

Gate valves are devices typically used in the wider sections of pipes to control the flow of liquids. They can be designed with rising stems or non-rising stems, solid wedges, flexible wedges, or with split wedges.

Gate valves Suppliers divided the gate valve types into two main types: Parallel and wedge-shaped valves.

Furthermore so-called gate valves are the common types of valves used in industries such as textiles, power generation, refineries, petrochemical plants, shipbuilding, food plants, the chemical industry and paper factories.

Advantages

Gate valves contain very low friction loss

They provide laminar flow, a pressure loss is minimum

Suitable to use in high temperature and pressure conditions.

Applications

It allows materials being transported to flow in a straight line with nothing blocking its flow.

Gate valves are especially advantageous when they are used to halt the flow of liquids, when the partial flow cause irrevocable damage to pipe lines and systems.

Are you searching for a industrial valves manufacturers and valves suppliers for your business pipeline? Valvulasfevisa, leading European valve manufacturers and suppliers across the global.

We have different types of industrial valves like check valves, control valves, fire valves etc . Our Europe origin valves are good in packing, dispatching and after sales service and our uncompromising quality makes the buyer to approach us for future dealings.

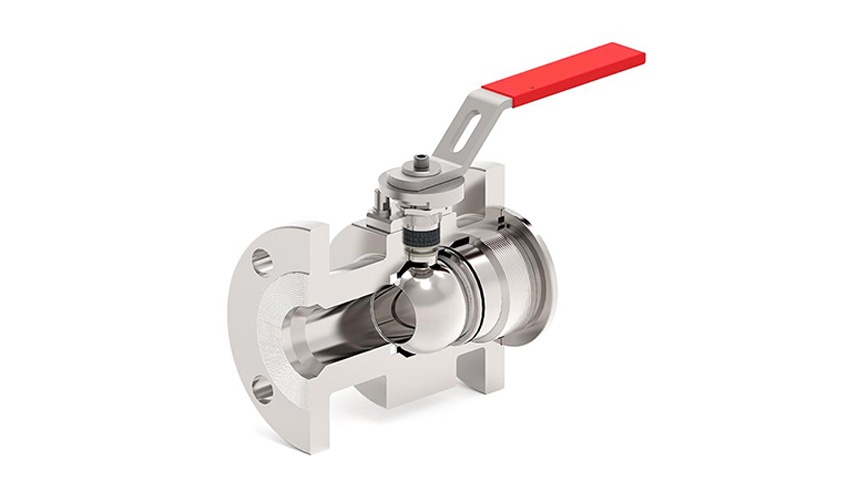

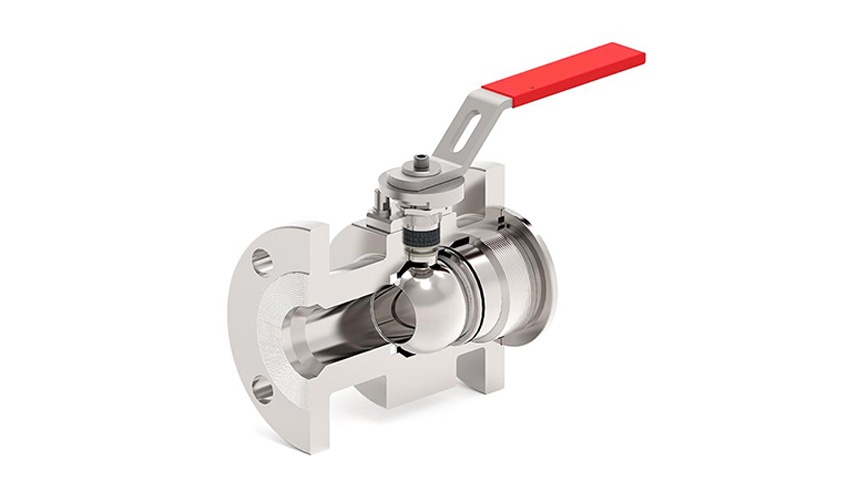

Ball Valve

Ball valve is part of the quarter turn valve family. The distinct feature of a ball valve is its hollow ball-shaped disc that acts to stop or start media flow. The ball disc is one of the quickest valves because it only needs a quarter turn to open or close.

Advantages

● Great shut on/off capability.

● Minimal leakage through wear & tear if properly used.

● Low maintenance cost.

● Minimal pressure drop.

● Time & labor effective to operate.

Disadvantages

● Not suitable as control or throttling valve.

● Not suitable for thicker media as sedimentation could occur and damage the valve disc & seat.

● Surge pressure could occur due to rapid closing and opening.

Applications

Ball valves are suitable for fluid, gaseous and vapor applications that need bubble-tight shutting down. While primarily for low pressure uses, high pressure and high temperature applications apply to ball valves with metal seats.